BY: LAUREN SIPPLE

A Brief History of Sour Beer

When beer was first invented (or perhaps more accurately, discovered), it consisted of two ingredients: grain and water. Although unbeknownst to the people of the time, wild yeast such as Saccharomyces were responsible for fermentation. Other microbes, such as lactic acid bacteria, were likely present and aided in the brewing process. Acidification by lactobacilli helped to prevent growth of other microbes in the beer, provided a favorable growth medium for Saccharomyces, and increased the availability of starch by “softening” protein sheaths surrounding starch granules (Hornsey, 2003). Lactic acid production also results in tartness, so it is likely in the early days of brewing, most beer would sour days after brewing. While at the time it was not known, microorganisms such as Lactobacillus, Streptococcus, Staphylococcus, Micrococus, Bacillus, and Pediococus can spoil beer and produce unpleasant aromatic compounds.

The addition of hops assisted in preventing souring of beer. Hops were regularly mentioned for their use in brewing beginning in the 13th century. Early brewers noted that beer brewed with hops had an extended shelf life. Although it was not known at the time, this was due to the antimicrobial properties of hops imparted by bittering β-acids, α-acids, and iso-α-acids from the hop cone. Iso-α-acids act as proton ionophores, transporting protons across cell membranes of spoilage microbes and impeding proton motive force, ultimately killing the cell (Karabin et al, 2016; Bokulich & Bamforth, 2013). The use of single strain yeast became common in the 19th century spurred by Louis Pasteur’s Studies on Fermentation: The Diseases of Beer, Their Causes, and the Means of Preventing Them. This resulted in more clean, consistent beer, such as pale lagers. (Tonsmeire, 2014).

The combination of hops and single strain yeast created beer with a longer shelf life that was easily shipped, and therefore drove the development of many of the beer styles in the United States. While sour-style beers from other countries persisted, such as Belgian Lambics, it wasn’t until the 1990s that American craft breweries began to pursue ventures in sour beer. Since then, the sour beer segment has grown tremendously (Tonsmeire, 2014). Sour beer encompasses a wide variety of beer styles, including Lambic, gueuze, Flemish red, Gose, Berliner Weisse, barrel-aged, and kettle soured beers.

Sour Beer Microbiology

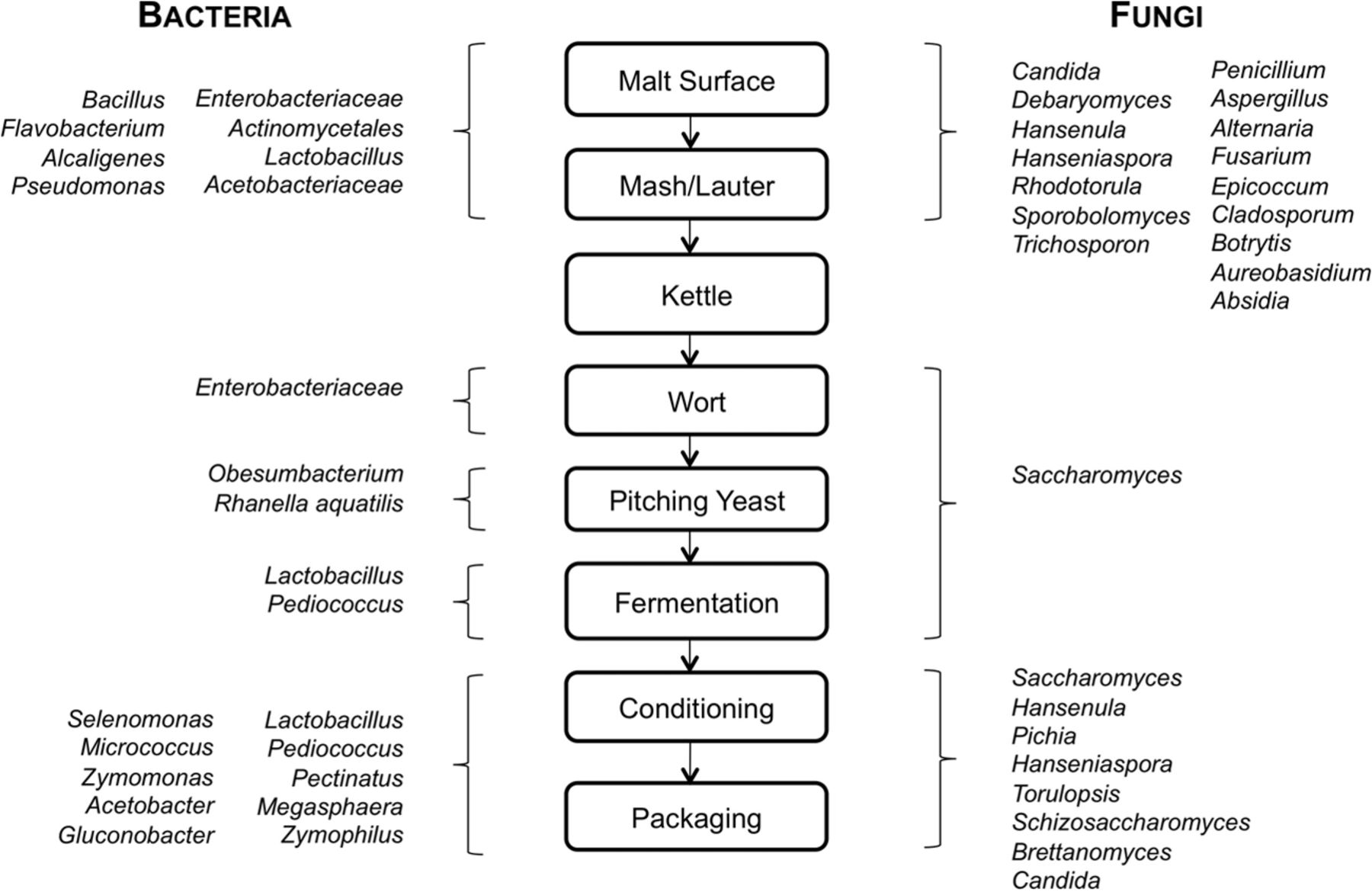

In 99% of beer, the only microbe present is Saccharomyces, and the presence of anything else is indicative of beer defects (Bokulich & Bamforth, 2013). These non-Saccharomyces cultures are introduced to the brewing process through ingredients or the brewing environment, and may be prevalent during different points in the brewing process (Figure 1).

Some beer spoilage microorganisms include Brettanomyces, Lactobacillus, and Pediococcus. Such microbes spoil beer through acidification and haze formation, among other things (Bokulich & Bamforth, 2013). However, these traits are intentionally sought after in the brewing of sour beer. Some of the primary organisms responsible for beer souring are discussed here.

Figure 1. “Microbiota of malting and brewing. The diagram shows an overview of bacterial and fungal species previously reported at all major stages of beer production” (from Bokulich & Bamforth, 2013).

Brettanomyces

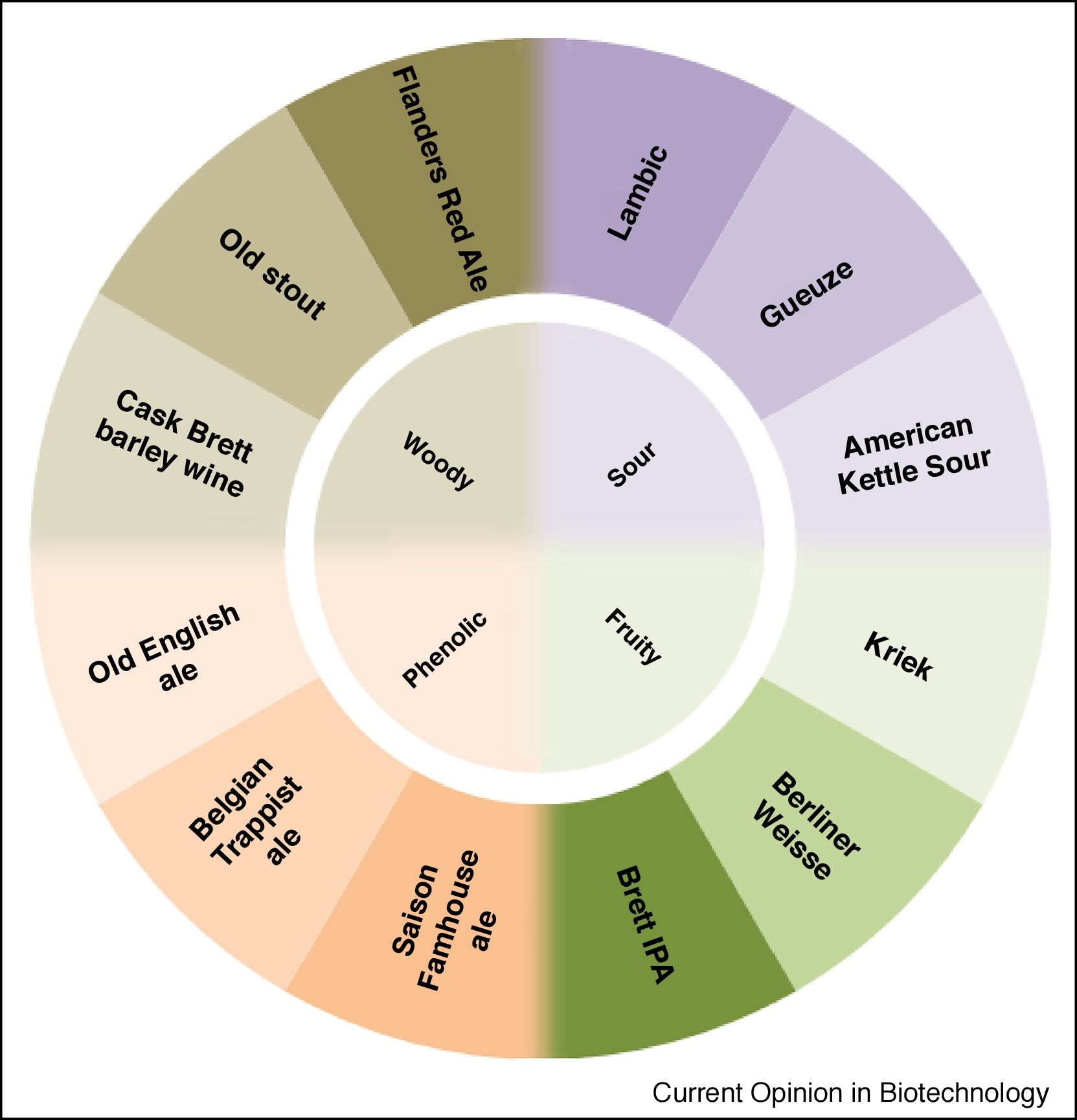

Brettanomyces is the most commonly used non-conventional brewing yeast. When introduced unintentionally to a “clean” (non-sour) beer, Brettanomyces can cause undesirable off-flavors, including horse sweat, barnyard, medicinal or leathery (Malfeito-Ferreira, 2018). However, Brettanomyces added intentionally or as a part of the spontaneous fermentation of gueuze and Lambic beer produces compounds that yield unique flavors unachievable through use of only Saccharomyces yeast (Figure 2).

Brettanomyces uses molecules that Saccharomyces cannot, such as dextrins, cellobiose, and nitrate. Brettanomyces does not produce glycerol, and is able to produce acetic acid at higher amounts than Saccharomyces. Ethyl esters are also produced in high quantities, contributing to tropical fruit and pineapple flavors. The production of volatile phenols, including 4-ethylphenol (4-EP) and 4-ethylguaiacol (4-EG), also contribute to flavor from Brettanomyces (Colomer et al, 2019). While high amounts of 4-EP can impart undesirable band-aid or medicinal off-flavors, moderate amounts of 4-EG contribute a spiciness that is characteristic of beer fermented with Brettanomyces (Holt et al, 2018).

Brettanomyces has high β-glucosidase activity, which allows it to break down cellobiose present in wood. Beer with Brettanomyces is thus a good candidate for barrel-aging. β-glucosidase activity can also release flavor active compounds from hops, resulting in an increase in volatile compounds such as linalool, which has a citrusy aroma and flavor (Colomer et al, 2019).

Figure 2. “Shown are the most common beer styles that Brettanomyces species can contribute to with its flavor properties. Brettanomyces beer styles have been arranged based on their most predominant flavor out of the 4 most common organoleptic properties woody, sour, phenolic and fruity found in Brettanomyces beers. Nonetheless every beer style holds substantial complexity and can exhibit characters from other categories.” (from Colomer et al, 2018).

Lactic Acid Bacteria (LAB)

Pediococcus and Lactobacillus are the two types of microbes generally responsible for lactic acid production in sour beer, although Leuconostoc, Lactococcus, and other LAB have also been isolated in sour beer (Bokulich et al, 2012).

The main strain of Pediococcus used in brewing sour beer is P. damnosus, which is hop-tolerant. The advantage of utilizing Pediococcus in sour beer is that it takes time for it to begin lowering the pH dramatically, which gives the primary yeast strain time to complete fermentation of the wort. Pediococcus can produce beer with high acidity, lowering the pH below 3.0. The main disadvantage to souring beer with Pediococcus is that it produces diacetyl, resulting in a buttery note that is considered undesirable in many styles of beer. For this reason, Pediococcus may be used in conjunction with Brettanomyces, which is able to convert diacetyl into less flavorful byproducts (Tonsmeire, 2014).

Lactobacillus, a gram-positive bacterial, is largely inhibited by the activity of iso-α-acids in hops. This is, after all, why hops are typically added to “clean” beer — to prevent spoilage by microbes such as Lactobacillus. However, there are techniques available for using Lactobacillus in brewing sour beer, such as sour mashing and the utilization of hop tolerant strains. Lactobacillus can lower the pH of sour beer to approximately 3.3-3.4 (Tonsmeire, 2014).

The Science of Sour

The Wild Side: Spontaneous Souring

Lambic and gueuze beers are some of oldest types of beers brewed today. These beers are fermented spontaneously rather than by addition of yeasts or starter cultures. Lambic beers were traditionally brewed in the Senne river valley near Brussels, Belgium, giving traditional Lambics a microbial terroir of sorts. There are many breweries that attempt to mimic this style. For instance, beers brewed in the United States using this method are known as “American coolship ales” (Bokulich & Bamforth, 2013).By cooling the wort slowly in an open vessel and allowing it to ferment and age in a wooden cask, yeasts, LAB, and acetic acid bacteria are introduced to the beer from the brewing environment. These “wild microbes” produce variety of metabolites that contribute to Lambic flavor.

The microbial diversity and succession of growth in spontaneously fermented beers is complex. This succession is typically broken into four phases:

1. Enterobacteriaceae phase: Starts a few days after fermentation and lasts approximately one month. Characterized by enterobacteria, including Klebsiella, Enterobacter, Escherichia, Citrobacter, Serratia, and Pectobacterium, as well as non-Saccharomyces yeast.

2. Main fermentation phase: Starts approximately one month after fermentation begins. Characterized by typical brewing yeast, Saccharomyces

3. Acidification phase: Occurs in the 3-8 months after fermentation begins. Characterized by LAB such as Lactobacillus, Brettanomyces, and

4. Maturation phase: Begins after 10 months of fermentation. Characterized by Brettanomyces, attenuation of the microbes present in the wort (Van Oevelen et al, 1977; Bokulich & Bamforth, 2013; Spitaels et al, 2014).

Inoculation for Acidification

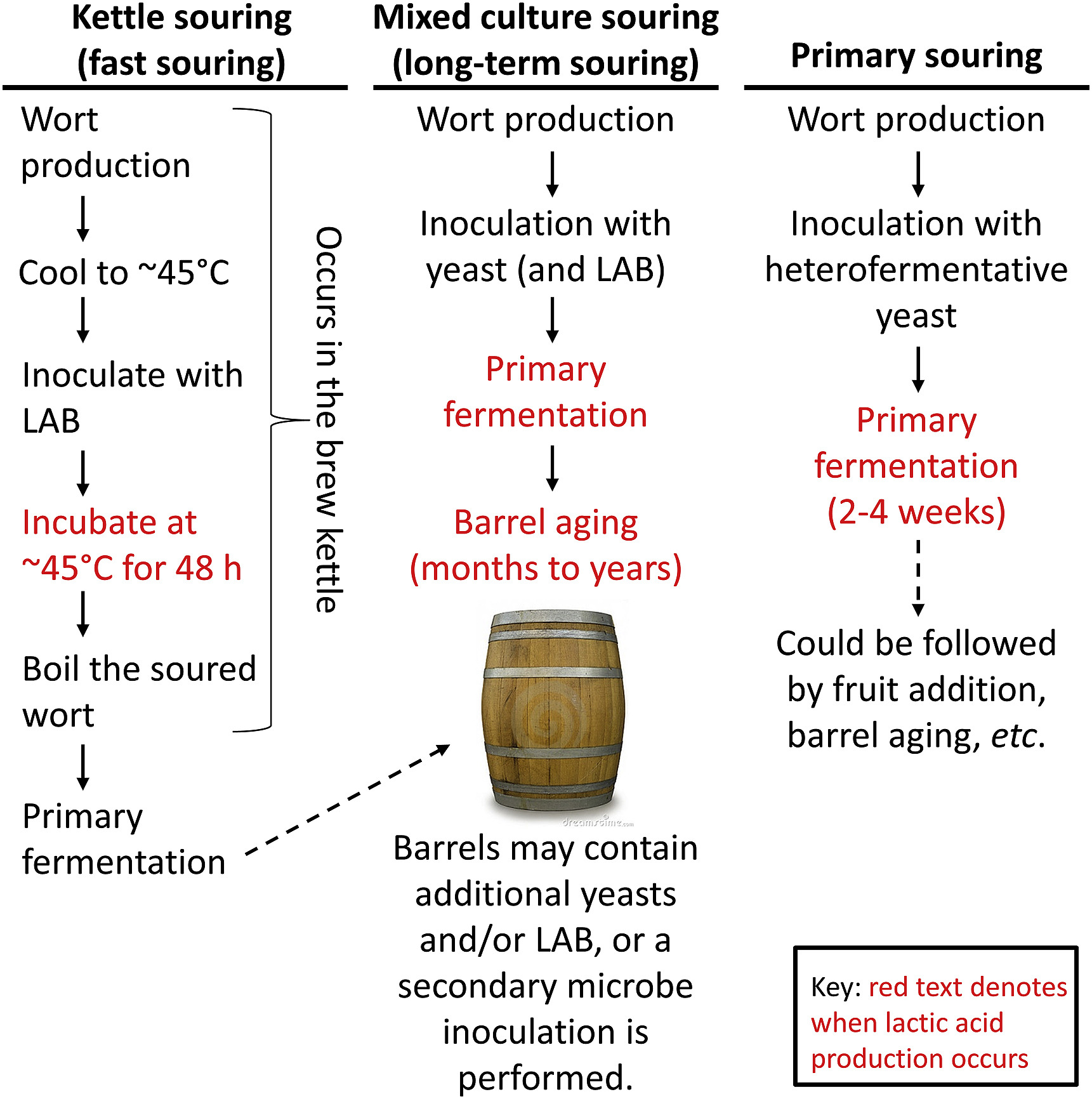

There are two primary methods for souring beer. These include kettle souring and mixed culture fermentation (Figure 3).

Figure. 3. Comparison of kettle souring (left), wood-aged souring (center), and primary souring (right) (from Osburn et al, 2018).

Kettle Souring

Kettle souring, which is the more modern of the two techniques, occurs in the brew kettle. Wort with little or no hop addition is produced and cooled to incubation temperature (40-45°C), then is inoculated with LAB. LAB may be introduced through pure cultures or addition of grain. The wort is fermented by the LAB until the desired level of sourness is achieved, which typically takes 24-48 hours. The wort is then boiled again to kill the LAB and stop souring of the beer. The wort can be hopped during/after the second boil to contribute bitterness and microbial protective effects to the beer. After the boil, the wort can be inoculated with brewing yeast to initiate primary fermentation.

This souring method is relatively quick; however, boiling the wort after fermentation by LAB drives off some flavor compounds produced during souring, making the beer less complex. This method also requires the wort to sit in the brew kettle for an extended period, preventing breweries from beginning other batches of beer (Osburn et al, 2018).

Mixed Culture Fermentation

Mixed culture fermentation is the more traditional method for making sour beer. In this method, the wort is hopped only lightly, as hops inhibit the growth of LAB. LAB and/or Brettanomyces can added to the fermenter just before or at the same time as brewer’s yeast, in which case souring begins during primary fermentation. LAB and/or Brettanomyces may also be introduced after primary fermentation during barrel aging, where the fermented beer is allowed to age in a barrel for an extended period until the desired pH and flavor profile are achieved. The introduction of these microbes may take place through the inoculation of pure cultures, or through the use of barrels that inherently have LAB, Brettanomyces or other microbes present as part of the natural flora (Osburn et al, 2018). Perhaps the most challenging aspect of utilizing mixed culture fermentation is controlling the optimum balance between the microorganisms involved so that the desired flavor profile is achieved. Additionally, his method makes it difficult to detect and control contamination or spoilage while the beer ferments (National Research Council (US) Panel on the Applications of Biotechnology to Traditional Fermented Foods, 1992).

Other Souring Methods

Other techniques do exist for souring beer. These may include acidulating the malt or mash. Acidification during the malting process utilizing LAB has a multitude of benefits, including increased malt yield and improved mash and wort filterability. In addition, LAB help with the malting process by contributing to barley germination and malt modification (Vriesekoop et al, 2013).

In sour mashing, Lactobacillus is added to the mash before hops are added to the wort (Tonsmeire, 2014). The grain is mashed as normal, then the temperature of the mash is lowered before inoculation with Lactobacillus. The temperature is held at approximately 115-120°F and the mash is allowed to ferment until it reaches a pH of approximately 3.0-3.7. The challenge of sour mashing is holding the mash at a lowered temperature for an extended period increases the risk of infecting the mash with spoilers such as Clostridium, which can produce butyric acid and cause “cheesy” or rancid off-flavors (Goldman, 2017; Hawthorne et al, 1991).

Another technique for souring beer without LAB was proposed by Osburn et al (2018). Primary souring, or inoculating the beer with a yeast other than S. cerevisiae capable of heterofermentation, allows beer to be soured during primary fermentation without the use of LAB. Using this method, breweries do not have to introduce LAB, which have the potential to spoil traditionally “clean” beers. Beer produced through primary souring also retains aromatics that are boiled off by methods such as kettle souring. However, primary souring methods are still being developed, as yeasts capable of primary fermentation tend to be much less efficient in completing fermentation than typical commercial ale yeasts. Yeasts such as Hanseniaspora vineae, Wickerhamomyces anomalus, and Schizosaccharomyces japonicus show promise for use as primary souring yeast. Each produce lactic acid at levels comparable to LAB and are hop tolerant (Osburn et al, 2018).

Summary

Brewing sour beer is an art as well as a science. There are many different avenues for producing sour beer, offering breweries the opportunity to pursue new beverages and diversify their brews. However, these beers are more time consuming and challenging to brew in comparison to “clean” beer. Unique sour beer challenges include increased difficulty in reproducing beers as well as increased risk of contaminating other beers, as their main microbial components are generally categorized as beer spoilers. Nonetheless, the sour beer trend continues to grow, with more breweries producing sour styles and sales continuing to increase.

Want to learn more? Follow us on Instagram and Facebook for quick updates on seminars, events, and food science!

References

Bokulich, N. A., & Bamforth, C. W. (2013). The microbiology of malting and brewing. Microbiology and Molecular Biology Reviews, 77(2), 157-172. doi:10.1128/mmbr.00060-12

Bokulich, N. A., Bamforth, C. W., & Mills, D. A. (2012). Brewhouse-resident microbiota are responsible for multi-stage fermentation of American Coolship Ale. PLoS ONE, 7(4), e35507. doi:10.1371/journal.pone.0035507

Colomer, M.S., Funch, B., & Forster, J. (2019). The raise of Brettanomyces yeast species for beer production. Current Opinion in Biotechnology, 56, 30-35. doi:10.1016/j.copbio.2018.07.009

Goldman, J. (2017, August). Sour mash secrets. Retrieved from https://beerandbrewing.com/sour-mash-secrets/

Hawthorne, D. B., Shaw, R. D., Davine, D. F., Kavanagh, T. E., & Clarke, B. J. (1991). Butyric acid off-flavors in beer: Origins and control. Journal of the American Society of Brewing Chemists, 49(1), 4-8. doi:10.1094/asbcj-49-0004

Holt, S., Mukherjee, V., Lievens, B., Verstrepen, K. J., & Thevelein, J. M. (2018). Bioflavoring by non-conventional yeasts in sequential beer fermentations. Food Microbiology, 72, 55-66. doi:10.1016/j.fm.2017.11.008

Hornsey, I. S. (2003). A history of beer and brewing. Cambridge, UK: Royal Society of Chemistry.

Karabín, M., Hudcová, T., Jelínek, L., & Dostálek, P. (2016). Biologically active compounds from hops and prospects for their use. Comprehensive Reviews in Food Science and Food Safety, 15(3), 542-567. doi:10.1111/1541-4337.12201

Malfeito-Ferreira, M. (2018). Two decades of “horse sweat” taint and Brettanomyces yeasts in wine: Where do we stand now? Beverages, 4(2), 32. doi:10.3390/beverages4020032

National Research Council (US) Panel on the Applications of Biotechnology to Traditional Fermented Foods. Applications of Biotechnology to Fermented Foods: Report of an Ad Hoc Panel of the Board on Science and Technology for International Development. Washington (DC): National Academies Press (US); 1992. 6, Mixed-Culture Fermentations. Available from: https://www.ncbi.nlm.nih.gov/books/NBK234678/

Osburn, K., Amaral, J., Metcalf, S. R., Nickens, D. M., Rogers, C. M., Sausen, C., … Bochman, M. L. (2018). Primary souring: a novel bacteria-free method for sour beer production. Food Microbiology, 70, 76-84. doi:10.1101/121103

Spitaels, F., Wieme, A. D., Janssens, M., Aerts, M., Daniel, H., Van Landschoot, A., … Vandamme, P. (2014). The microbial diversity of traditional spontaneously fermented Lambic beer. PLoS ONE, 9(4), e95384. doi:10.1371/journal.pone.0095384

Tonsmeire, M., & Cilurzo, V. (2014). American sour beer: Innovative techniques for mixed fermentations.

Van Oevelen, D., Spaepen, M., Timmermans, P., & Verachtert, H. (1977). Microbiological aspects of spontaneous wort fermentation in the production of Lambic and Gueuze. Journal of the Institute of Brewing, 83(6), 356-360. doi:10.1002/j.2050-0416.1977.tb03825.x

Vriesekoop, F., Krahl, M., Hucker, B., & Menz, G. (2012). 125th anniversary review: Bacteria in brewing: The good, the bad and the ugly. Journal of the Institute of Brewing, 118(4), 335-345. doi:10.1002/jib.49

Leave a Reply